Understanding Membrane Bioreactors: The Future of Wastewater Treatment

Membrane bioreactors (MBRs) stand for a significant innovation in the field of wastewater treatment, integrating biological processes with advanced membrane filtering to improve effluent high quality. As worldwide water deficiency and stringent regulative frameworks become increasingly pressing concerns, MBR modern technology offers an effective reaction through its capacity to reduce impact and enhance source recovery. The adoption of MBRs is not without its challenges, which warrant cautious consideration. What are the key variables influencing their execution and long-term stability in different contexts? The answers might reshape our strategy to wastewater administration.

What Are Membrane Bioreactors?

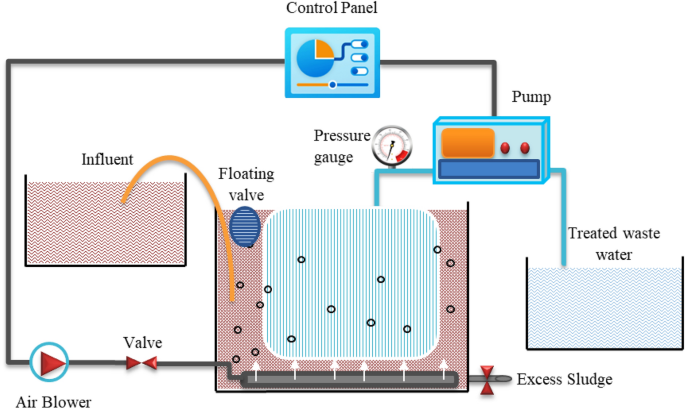

The core parts of MBR systems include a bioreactor where microbial activity occurs and a membrane system that filterings system the mixed liquor. This double functionality enables the synchronised destruction of raw material and solid-liquid splitting up in a solitary step. MBRs can operate in both immersed and outside configurations, with submerged systems being extra typical because of their compact layout and operational efficiency.

The fostering of MBR technology has obtained traction in various applications, varying from local wastewater treatment to commercial effluent management. MBRs are specifically beneficial in circumstances where space is minimal or strict effluent quality requirements must be satisfied. By maintaining a high concentration of microbes within the bioreactor, MBRs enhance the destruction of organic contaminants, thus generating higher therapy efficiencies compared to typical approaches.

Secret Advantages of MBR Technology

The integration of biological therapy with membrane layer purification in MBR systems supplies countless benefits that establish it in addition to typical wastewater therapy methods. One of the key advantages is the improved effluent high quality. MBRs efficiently remove suspended solids and pathogens, attaining higher levels of filtration that satisfy strict discharge standards and promote water reuse applications.

Another significant advantage is the minimized sludge manufacturing. MBR systems create much less excess sludge, bring about reduced disposal costs and a decrease in environmental impact. The closed nature of the membrane system minimizes the risk of odor emissions and enhances overall process control.

Lastly, MBRs are versatile and adaptable, making them ideal for numerous wastewater kinds, consisting of commercial and local sources. The ability to integrate with advanced therapy modern technologies better improves their efficiency, making MBRs an appealing service for the future of wastewater management.

Challenges and Limitations of MBRs

While MBR modern technology supplies many advantages, it also encounters a number of difficulties and limitations that can influence its extensive adoption. One significant obstacle is the high funding and operational prices connected with MBR systems. The initial financial investment for membrane materials and the essential facilities can be substantial, making it much less available for smaller sectors or communities.

Additionally, membrane layer fouling remains a critical problem that can diminish system efficiency and increase upkeep needs. Fouling happens when solids, raw material, or microbes build up on the sites membrane layer surface, causing reduced leaks in the structure and calling for regular cleansing or replacement.

One more constraint involves read more the complexity of the modern technology. MBR systems require knowledgeable personnel for operation and upkeep, which can be an obstacle in regions with restricted technological knowledge. In addition, the disposal of spent membranes provides ecological concerns, as the materials are commonly not naturally degradable and can add to waste management difficulties.

Lastly, while MBRs can efficiently treat a wide variety of wastewater, they might not be ideal for all applications, specifically those with high focus of fats, oils, and oils, demanding more study and technology to resolve these constraints.

Applications of Membrane Layer Bioreactors

In numerous fields, membrane layer bioreactors (MBRs) have actually emerged as a versatile option for wastewater therapy (Membrane Bioreactor). Their applications cover community, industrial, and agricultural setups, showcasing their flexibility and efficiency in diverse environments. In municipal wastewater therapy plants, MBRs dramatically boost effluent high quality, permitting water reuse and decreasing the environmental influence of released wastewater

Industrially, MBRs are employed in food and drink handling, textile production, and pharmaceutical manufacturing, where they read this article efficiently treat high-strength waste streams. Their capacity to manage varying and rising and fall tons contaminant focus makes them especially valuable in these fields. Furthermore, MBRs facilitate the elimination of pathogens, put on hold solids, and raw material, contributing to conformity with stringent discharge laws.

In agriculture, MBRs are significantly used for dealing with agricultural drainage and livestock wastewater, making it possible for the recovery of nutrients for plant food production. They likewise help in the treatment of greywater for watering, advertising sustainable water monitoring practices.

The convenience of MBRs is further confirmed by their assimilation with other modern technologies, such as anaerobic digestion and advanced oxidation procedures, boosting general efficiency and source recovery in wastewater treatment systems.

The Future of Wastewater Therapy

Innovations in technology and a growing focus on sustainability are forming the future of wastewater treatment. Membrane bioreactors (MBRs) exemplify this change by incorporating organic treatment processes with membrane purification, causing top notch effluent ideal for reuse. The fad towards circular economic situations is prompting facilities to adopt MBRs for their capability to recoup sources, such as water and nutrients, from wastewater.

Developments in membrane materials and setup are improving the effectiveness and long life of MBR systems, lowering functional prices and power intake. Smart technology integration, consisting of real-time surveillance and automated control systems, is more maximizing efficiency and making it possible for anticipating upkeep, hence decreasing downtime.

In addition, social assumptions and regulative pressures are pushing municipalities and industries to adopt even more lasting methods. Membrane Bioreactor. The shift in the direction of decentralized wastewater therapy remedies is obtaining grip, enabling for localized therapy that minimizes transportation costs and power usage

Conclusion

Membrane layer bioreactors (MBRs) stand for a transformative method to wastewater treatment, incorporating biological processes with innovative membrane layer technology. The benefits of MBRs, including enhanced effluent top quality, lowered spatial demands, and lower sludge manufacturing, position them as a viable solution amidst growing urbanization and more stringent environmental regulations. Regardless of existing challenges, the ongoing development in membrane layer materials and functional techniques assures to boost the efficacy and fostering of MBRs, ensuring their essential role in the future of lasting wastewater monitoring.

Membrane bioreactors (MBRs) represent a noteworthy innovation in the field of wastewater treatment, integrating biological procedures with sophisticated membrane filtration to enhance effluent high quality.Membrane layer bioreactors (MBRs) incorporate organic therapy processes with membrane filtration to efficiently treat wastewater.The combination of organic treatment with membrane filtering in MBR systems supplies numerous advantages that establish it apart from conventional wastewater treatment methods. Membrane bioreactors (MBRs) exhibit this change by incorporating organic therapy processes with membrane filtering, resulting in top notch effluent ideal for reuse.Membrane bioreactors (MBRs) represent a transformative approach to wastewater treatment, integrating biological processes with advanced membrane innovation.